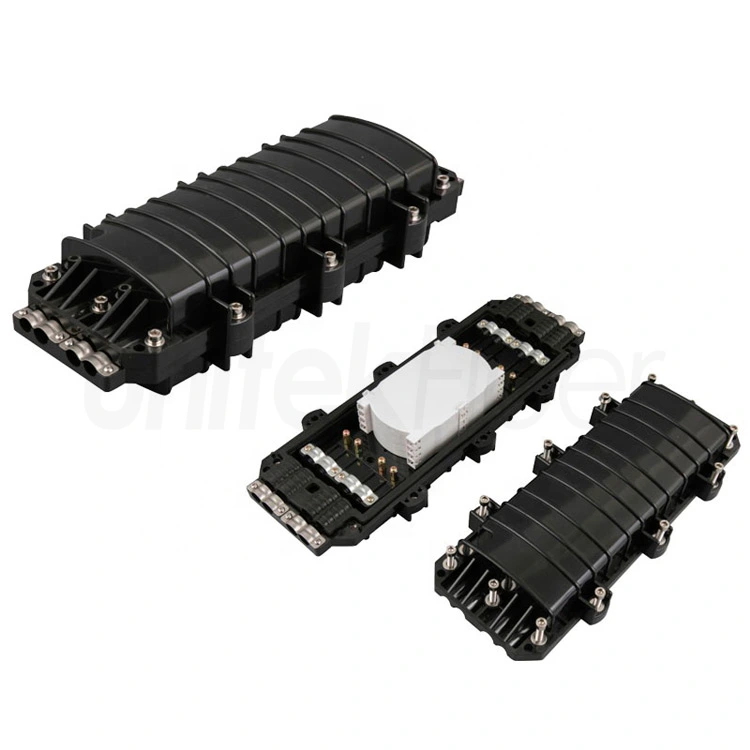

Part number: UNFOSC-HM144-03

In the construction and maintenance of the fiber optic splice closure, when the connection needs to be repaired, there is no need to cut off the optical cable. You only need to open the fiber optic splice closure, and then encapsulate it after the repair. This saves time for repairing the fault by using the remaining length of the optical fiber in the sheath. It is of great significance to improve economic efficiency and ensure smooth communication.

The fiber optic splice closures are widely used in network systems, CATV cable television, fiber optic cable network systems, etc.This fiber optic splice closure is used for the protection of various optical cable straight-through connections and branch connections, and can be buried, overhead, wall-mounted and duct-mounted. The whole set of fiber optic splice closure plastic parts are made of scientifically formulated high-strength PC synthetic engineering plastics, which are injection molded by numerical control equipment, which can effectively prevent material aging caused by cold, heat, oxygen and ultraviolet rays in nature, and has excellent mechanical strength. The sturdy fiber optic splice closure shell and main structural parts can play a flame-retardant, waterproof, and shock-proof role, and at the same time protect the tension, flattening, impact, bending, twisting, and axial compression of the optical cables connection, and it can be used in the natural environment of -40℃ -- +75℃ for a long time.

1 The fiber optic splice closure is made of high-quality engineering plastics.

2.The fiber optic splice closure adopts secondary compression cable technology to ensure no additional attenuation of the optical fiber in the fiber splice joint closure.

3.The fiber optic splice closure has multiple reuse and capacity expansion functions.

4. The fiber optic splice closure is fixed and sealed with multiple stainless steel screws, which is reliable and excellent.

5. The fiber optic splice closure adopts high-quality elastomer rubber sealing material, which is formed by a mold at one time, so that the joint surface of the product is seamless. The sealing performance can be guaranteed, and it can be repeatedly opened and used repeatedly, which solves the construction problem. The fiber optic splice closure is quick and convenient to disassemble and assemble, and can withstand the strong temperature changes of nature for a long time, ensuring good sealing performance. The fiber splice joint closure has a spacious structure, and the splice tray adopts a superposition type, which is flexible in configuration and simple in installation. The bending radius of the optical fiber fully meets the international standard, and a certain space is designed for the coiling of the remaining optical fiber inside the fiber optic splice closure, and the optical fiber has no attenuation change in the fiber splice joint closure.

The fiber optic splice closure have 4 inlets and 4 outlets.

The shell material of the fiber splice joint closure is be made of PC/PP.

The protection level of the fiber splice joint closure box is IP68.

You can choose 24 ,48 ,72cores,etc, the maximum number of cores is 144.

The fiber optic splice closure can be used for both outdoors and indoors.

The fiber splice joint closure can be laid overhead, pipes ,poles.

This fiber splice joint closure adopts mechanical sealing.