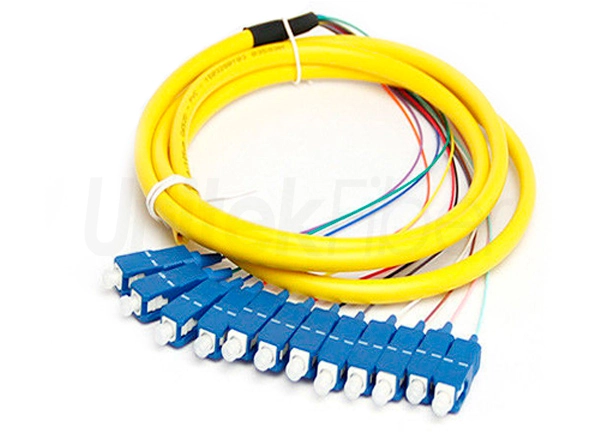

Fiber pigtail are divided into single mode and multimode fiber pigtail, which can be distinguished by color, wavelength and transmission distance. The color of the outer sheath of the multimode fiber pigtail is orange,aqua,red or green, the wavelength is 850nm, It is used for short-distance connection, and the color of the outer sheath of the single mode fiber pigtail is yellow, the wavelength is 1310m or 1550m, and its transmission distance is longer, up to 10km or 40km.

The fiber pigtails have an outer jacket that protects the tightly buffered cable from damage. The outer jacket can be easily stripped where space permits, so that the fiber pigtail has a tighter bend radius and takes up less space.

In addition, fiber pigtails are divided into single-mode fiber pigtails and multimode fiber pigtails, which can be distinguished by color, wavelength and transmission distance. The color of the outer sheath of the multimode fiber pigtail is orange OM1/OM2 and lake blue OM3, the wavelength of the multimode fiber pigtail is 850nm, the transmission distance is 500m, and it is used for short-distance connection; the color of the outer sheath of the single-mode fiber pigtail is yellow , the wavelength is 1310nm or 1550nm, and its transmission distance is longer, up to 10km or 40km.

There are two connection methods for optical fiber pigtails: mechanical splicing and fusion splicing:

1.The mechanical connection method

After the laid optical fiber and pigtail are stripped, cut and cleaned, they can be inserted into the splicing mating tray for alignment, tangency and locking.

2. The welding method

After the fusion splicing tool is ready, peel off the sheath of the laid optical fiber and fiber with wire strippers, clean and wipe the bare fiber with alcohol cotton, cut the optical fiber with a fiber cutter, and then use the fusion splicing tool under the protection of the splicing tray to fuse it into one.

lUsing high precision ceramic ferrule

lLow insertion loss and high return loss

lExcellent stability and high repetition

l100% Optic test (Insertion Loss & Return Loss)

lTelecommunication Network

lFiber Broad Band Network

lCATV system

lLAN and WAN system

lFTTP

The main difference between these materials is their fire-retardant properties, with LSZH offering the highest level of fire protection and OFNR being suitable for indoor riser applications. Additionally, LSZH has lower smoke emission and toxicity in case of burning compared to PVC, making it a preferred choice for sensitive environments like data centers and hospitals.

Yes, we have the Interferometer in our factory. We usually do the test when customers request.

OFNP have the highest rated fire retardant where it emits little smoke during combustion, LSZH cable jacket is composed of thermoset compounds that emit limited smoke and no halogen when exposed to high sources of heat.

strict sampling inspection on products before shipment and intact product packaging ensured.

Yep, no problem, they can be cut off and you can take the ones you need.

Unitekfiber supply a huge volume of fiber optic cable,most of fiber cable have a short lead time,7-10days.

Product worked great and arrived quickly.

Great product and fair price. Well described and fit in my project perfectly.

The cable was exactly what I needed. The shipping was fast and packaged extremely well.

Works just fine, performs as needed.And the shipping is fast.

Works as i expected. After i received the cable i started using it. It works great.