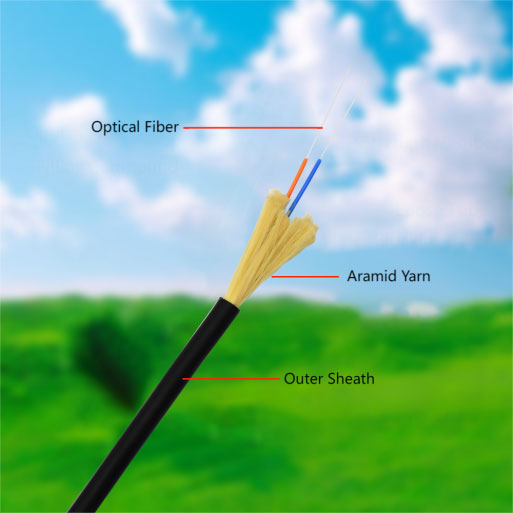

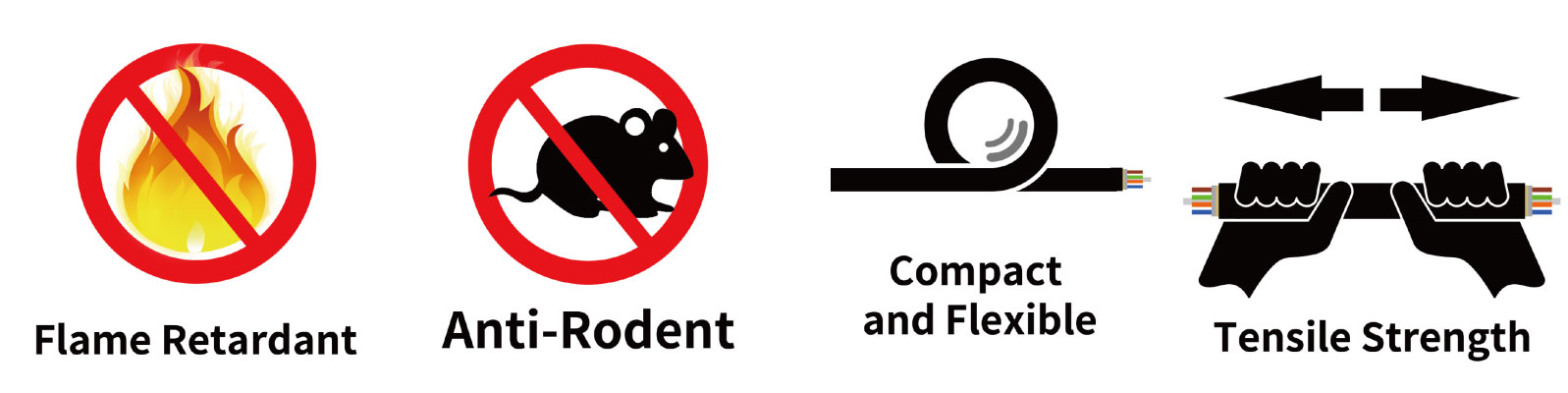

Indoor/outdoor tight buffered fiber optic drop cables are known for their ability to provide reliable and efficient data transmission in various applications. These tight buffer fiber drop cables consist of a 0.9mm tight buffered tube surrounded by aramid yarn strength members and jacketed with an LSZH-OFNR material. The tight buffer material provides direct contact with the optical fiber, offering additional protection during handling, routing, and connection procedures. This makes these tight buffered fiber optic drop cables an ideal solution for indoor and outdoor use. They can withstand harsh environmental conditions, such as exposure to UV radiation, moisture, and temperature variations, ensuring optimal performance and reliability.

Our indoor/outdoor tight buffer fiber optic drop cables have successfully obtained UL certification, ensuring their compliance with rigorous safety standards. This certification guarantees that our fiber drop cables meet requirements for fire resistance, low smoke emissions, and durability. With industry recognition and code compliance, optic drop cables provide a reliable and safe solution for various indoor and outdoor applications.

The Indoor/outdoor FTTH drop cables usually use aramid yarn or glass yarn.

Aramid yarn has excellent tensile strength and rigidity, which can effectively increase the durability and tensile capacity of fiber optic cables. When external force or tension is applied, aramid yarn plays a role in dispersing and absorbing stress, effectively preventing the fiber optic cable from being broken or damaged.

Glass yarn is also a commonly used reinforcing material with high hardness and compression resistance, which can provide an extra layer of protection to prevent some rodents (such as mice) from chewing fiber optic cables, causing signal interruption or fiber damage.

1. OFNR (Optical Fiber Nonconductive Riser) are designed for riser applications. They are used in spaces inside a building that connect floors, such as vertical zones or spaces between floors. These OFNR fiber optic cables are engineered to prevent the spread of fire from one floor to another within a building.

2. OFNP (Optical Fiber Nonconductive Plenum) are used inside buildings in plenum areas, the areas between a ceiling and the floor above it, where space is reserved for the circulation of air. At the same time, this OFNP fiber optic cable will not emit toxic smoke or steam.

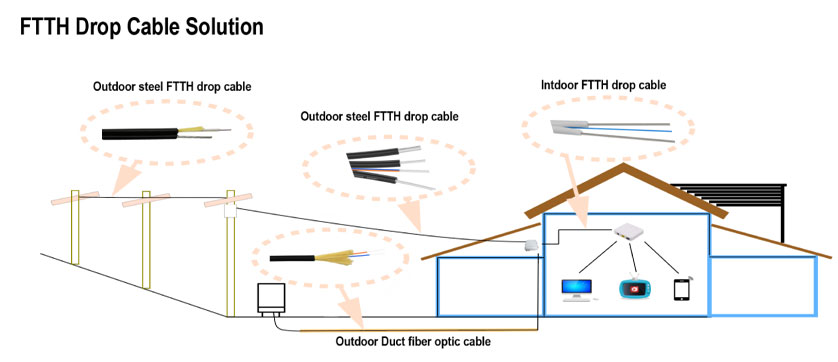

The indoor/outdoor fiber drop cable can withstand outdoor conditions while also meeting requirements for indoor use.

The difference between tight buffered and loose tube fiber optic cables is the construction. In tight buffered fiber optic cables, there isn't a gap between the fibre coating and cladding layers. Whereas loose tube fiber optic cables have a gap, either filled with gel or are loose in the cable.

If you need sample to test, please contact our sales team or email us sales@unitekfiber.com.

It depends on the quantity of the order. Normally it takes 5-7 working days.

Yes, we UnitekFiber as a professional manufacturer of fiber optic product, can provider OEM services.

The installation process was smooth, and the fiber optic drop cable delivered exceptional signal transmission.

The quality of the fiber optic drop cable is outstanding, providing reliable and high-speed connectivity. I'm extremely satisfied with my purchase.

The fiber optic drop cable's tight buffer construction offers superior protection against moisture, UV rays, and other environmental elements.

The fiber optic drop cable's tight buffer construction provides excellent resistance to bending and crushing, giving me peace of mind.

The fiber optic cable's tight buffer design makes it versatile for various applications and the signal quality is exceptional, resulting in fast and reliable data transfer.