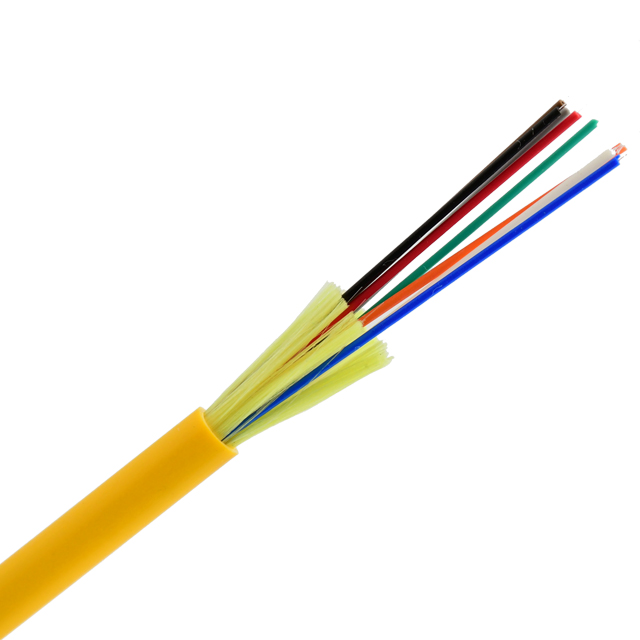

Fiber optic is a type of high-speed data transmission technology that uses thin, flexible glass fibers to transmit data over long distances. Despite its delicate appearance, fiber optic cable is actually much stronger than most people realize, making it an ideal choice for many different applications.

Optical fiber is made by an entirely different process. It starts with a pure silica rod or tube and the rest of the material is deposited at high temperature using ultra-pure gasses to create a preform. The preform is solidified, then placed in a drawing tower where the fiber is pulled into long strands. Careful control of the process makes the glass incredibly pure, transparent and strong.

One of the primary advantages of fiber optic cable is its strength and durability. Unlike copper wiring, which is prone to damage from bending and twisting, fiber optic cable can bend and flex without breaking or losing signal quality. This makes it highly resistant to damage from physical stress, such as accidental impact or environmental factors like extreme weather conditions.

In addition to its physical strength, fiber optic cable is also highly resistant to interference from electromagnetic fields or radio waves. This means that it can provide reliable data transmission even in environments where other types of cabling would be susceptible to interference or signal loss.

Another advantage of fiber optic cable is its ability to support high-speed data transmission over long distances. Because fiber optic cable uses light to transmit data, it can maintain signal quality over much longer distances than copper cabling. This makes it ideal for use in applications where data must be transmitted over long distances, such as telecommunications networks or data centers.

All fiber optic cables include strength members, typically aramid fibers such as Kevlar. Kevlar is strong, but its most important characteristic is that it does not stretch under tension. When pulled, it will not stretch, then relax when the tension is removed, which would cause kinks in the cable and put stress on the fiber. The amount of aramid fiber inside a typical indoor cable allows up to 200 pounds of pulling tension, while outdoor fiber optic cable are rated at 600 to 800 pounds of tension. An additional strength member is used as a stiffener to maintain the allowable cable-bend radius and prevent kinking when pulling around corners.

Despite its many benefits, fiber optic cable does require some special considerations when it comes to installation and maintenance. For example, it must be carefully installed and protected from damage during installation or routine maintenance procedures. Additionally, regular testing and monitoring are necessary to ensure that the cable is functioning properly and to identify any potential issues before they become more serious problems.

Overall, fiber optic cable is a highly robust and reliable technology that continues to grow in popularity as more organizations recognize its many advantages. Whether you are looking to build a high-speed network or simply need a reliable way to transmit data over long distances, fiber optic cable is a smart choice that is stronger than most people realize.

If you're looking for high-quality, customized SM MM fiber optic cable, look no further than www.unitekfiber.com. With a wide selection to choose from and a high quality, Unitekfiber is your go-to source for all your fiber optic needs.