ADSS fiber optic cable is also known as All-dielectric Self-supporting Fiber Optic Cable. ADSS fiber optical cable innovative structure has been meticulously crafted to provide optimal performance and exceptional durability, ensuring that it meets the highest standards of reliability in the field. UnitekFiber as a professional fiber optic cable manufacturer provides customized a serial of ADSS fiber cables. We produce 2-288cores single jacket and double jacket ADSS fiber optic cables with pole span up to 700 meters.

ADSS Fiber Optic Cable|All-dielectric Self-supporting Fiber Optic Cable Span 100m 200m Double Jacket PE

ADSS Fiber Optic Cable|All-dielectric Self-supporting Fiber Optic Cable Span 100m 200m Double Jacket PE

ADSS Fiber Optic Cable|Aerial Cable Outdoor Single Mode 48cores Stranded Loose Tube Span 50m Double Jacket

ADSS Fiber Optic Cable|Aerial Cable Outdoor Single Mode 48cores Stranded Loose Tube Span 50m Double Jacket

Hot Sales ADSS Fiber Optic Cable 12F 24F 48F 96F 144F G652D Single Mode Stranded Loose Tube Span Outdoor Aerial

Hot Sales ADSS Fiber Optic Cable 12F 24F 48F 96F 144F G652D Single Mode Stranded Loose Tube Span Outdoor Aerial

Best Design Aerial Mini ADSS Fiber Optic Cable All-dielectric Self-supporting ASU Fiber Optic Wire 12core 100m Span

Best Design Aerial Mini ADSS Fiber Optic Cable All-dielectric Self-supporting ASU Fiber Optic Wire 12core 100m Span

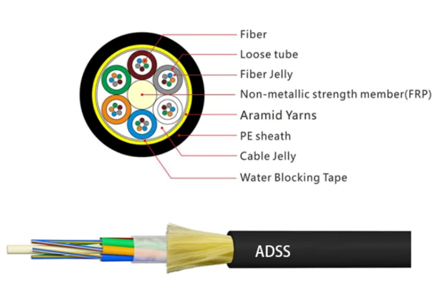

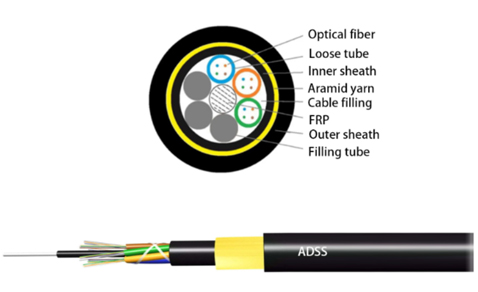

ADSS cable, All-dielectric Self-supporting Optical Cable (also known as All-dielectric self-supporting fiber optic cable). All-dielectric fiber optic cable is made of all-dielectric materials. Self-supporting means that the reinforcing member of the optical cable itself can withstand its own weight and external load. Because of its self-supporting, its mechanical strength is very important. The use of all-dielectric materials is due to the fact that the cable is in a high-voltage, high-energy environment and must withstand the effects of high voltage. Since it is used overhead on the power pole tower, it must have a matching pendant to fix the cable to the tower. That is, the ADSS cable has three key technologies: the mechanical design of the ADSS cable, the determination of the suspension point, and the selection and installation of the matching hardware.

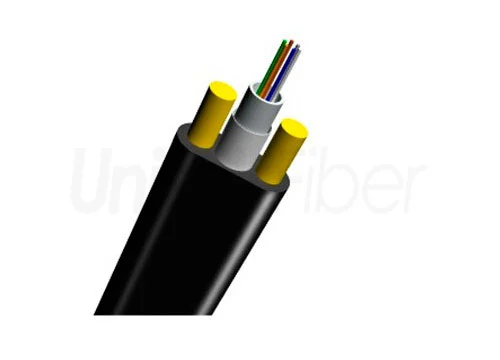

There are generally three kinds of structures for ADSS cables: central loose tube ADSS fiber cables, single jacket stranded ADSS fiber cables and double jacket stranded ADSS fiber cables.

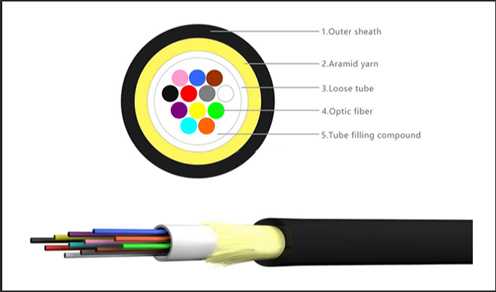

Aerial Central Tube Fiber Optic Cable, from the following picture, the ADSS fiber optic cable is placed in a PBT loose tube filled with water-blocking material. Then it is wrapped with aramid yarn according to the desired tensile strength and extruded with PE sheath. This structure has a smaller diameter and lighter weight. It is suitable for short distance pole span.

The single jacket ADSS cable is designed for the typically shorter pole span lengths of distribution and sub-transmission environments. The single jacket ADSS fiber optic cables are use for no more than 200 meters pole span. Having aramid yarn provides more sturdy structure, and the fiber loose tubes are surrounding around a central strength member (usually as FRP material) could providing high allowable tensile strength. For the right application, the single jacket ADSS fiber optic cables provide a cost-effective option while also reducing the size and weight compared to a similar double-jacket cable. The ADSS cable jackets are usually using PE jacket and AT jacket. PE sheath is used for power lines below 110KV. AT sheath is anti-tracking sheath and used for power lines above 100KV.

If the pole span more than 200 meters, UnitekFiber highly recommended double PE jacket ADSS fiber optic cable. The pole span of double jacket ADSS fiber optic cable could reach 700 meters. The double-jacket ADSS fiber cables allow for higher tensile strength with more aramid yarn. For this reason, double jacket designs are almost always required in transmission line applications where longer pole span lengths require greater tensile strength. Thereby, the double jacket ADSS cable could be withstanding the harsher environment.

The mechanical properties of ADSS fiber optic cable are mainly reflected in the maximum operating tension, average running tension and ultimate tensile strength of the ADSS cable. The ADSS cable is a self-supporting overhead cable, so it must withstand the long-term effects of its own gravity and must withstand the baptism of the natural environment. If the mechanical performance of the ADSS cable is not designed properly and is not compatible with the local weather, the ADSS cable will have a safety hazard and the life will be compromised. Therefore, each ADSS cable project must be designed with professional software according to the natural environment and span of the ADSS cable routing to ensure that the ADSS cable has sufficient mechanical strength. When the transmission line is already equipped with a ground wire and the remaining life is still quite long, it is necessary to build the optical cable system with low installation cost as soon as possible, and avoid the power outage operation.

UnitekFiber is a professional fiber optic cable factory, we also produce indoor fiber drop cables, duct fiber cables, figure 8 fiber cables and direct buried fiber optic cables etc. In addition to fiber optic cables, we also manufacture fiber optic patchcords, SFP optical transceiver and other fiber optic products for data center.

Air Blowing Micro Fiber Optic Cable

OSP Fiber Cable(Outside Plant Fiber Cable)

Breakout Indoor Fiber Optic Cable

Indoor Armored Fiber Optic Cable