The colored optical fiber and jelly are added to the loose tube made of high modulus plastics at the same time, and the optical fiber can be moved in the sleeve. Different loose sleeves are twisted along the central reinforcement core to form cable core. The cable core and protective material are added to make loose sheath stranded optical cable.

The main characteristics of loose tube stranded fiber cable are as follows:

Loose sleeve material itself has hydrolysis resistance and high strength. The tube is filled with special ointment to protect the optical fiber critically.

The reinforcing core is in the central position of the cable core, and the loose sleeve is twisted around the reinforcing core with appropriate twisting pitch. By controlling the excess length of the optical fiber and adjusting the twisting pitch, the cable has good tensile and temperature characteristics.

The loose tube and the reinforced core are joined together by filling and twisting with cable paste, which ensures the waterproof performance between the loose tube and the reinforced core.

Radial and longitudinal waterproofing of optical cable is guaranteed by various measures.

According to different requirements, there are a variety of measures against lateral pressure.

The prepared fiber cable band is stacked in the spiral skeleton groove to form the cable core. The core of the cable and the protective material are added to form a skeleton type optical fiber ribbon cable.

The main characteristics of skeleton fiber-optic ribbon cable are as follows:

The optical fiber assembly density is high, and the diameter of the optical cable is relatively small.

The skeleton is made of high density polyethylene, which has good lateral compression resistance, good protection for optical fibers, and can prevent damage to optical fibers when stripping optical cables.

The skeleton groove rotates spirally along the cable to ensure that the fiber placed in the groove has enough excess length, and to ensure the tensile, bending and temperature characteristics of the cable.

The fiber cable is filled with water-blocking tape instead of ointment, which not only guarantees the water-blocking performance of fiber optic cable, but also greatly improves the connecting efficiency and facilitates construction and maintenance.

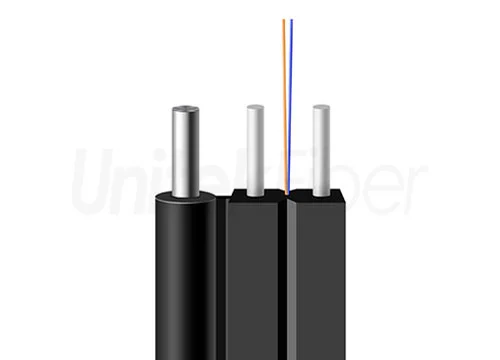

The optical fiber is inserted into the spiral space loose tube made of high modulus plastic. The sleeve is filled with waterproof compound. A layer of water-resisting material and armor material are applied outside the tube. Two parallel wires are placed on both sides and polyethylene sheathed cable is extruded.

The main characteristics of helical central tube optical cable are as follows:

The unique design of spiral grooved loose sleeve is conducive to accurately controlling the excess length of the optical fiber, and ensures that the optical cable has good mechanical properties and temperature characteristics.

Loose tube material itself has good hydrolysis resistance and high strength. It is filled with special ointment to protect the optical fiber critically.

Two parallel wires ensure the tensile strength of the cable.

Small diameter, light weight and easy laying.

As one of leading fibre cable suppliers, Unitek fiber offer: