Fiber Optic Cable types

Optical fibers can be divided into single-mode and multi-mode according to the transmission mode.

Single-mode optical fiber

Single mode optical fiber transmits only one mode of optical signal. Conventionally, there are transmission grade classifications such as G.652, G.653, G.654, and G.655. Single-mode optical fiber can transmit hundreds of megabytes of signals up to tens of kilometers. Single-mode fiber only transmits the main mode, that is to say, the light is only transmitted along the inner core of the fiber. Because the mode dispersion is completely avoided, the transmission frequency band of single-mode fiber is very wide, so it is suitable for large-capacity, long-distance optical fiber communication , Single-mode fiber uses light wavelength of 1310nm or 1550nm.

Multi-mode optical fiber

Multi mode optical fiber can transmit multiple modes of optical signals. It is of the G.651 level. According to the optical mode, it is divided into OM1, OM2, and OM3. The maximum transmission distance of multi-mode optical fiber for transmitting 100M signals is 2 kilometers. Multimode fiber, under a certain working wavelength, there are multiple modes transmitted in the fiber. This fiber is called multimode fiber. Due to dispersion or aberration, the transmission performance of this fiber is poor. The frequency band is relatively narrow and the transmission capacity It is relatively small and the distance is relatively short.

Optical cable laying methods and requirements

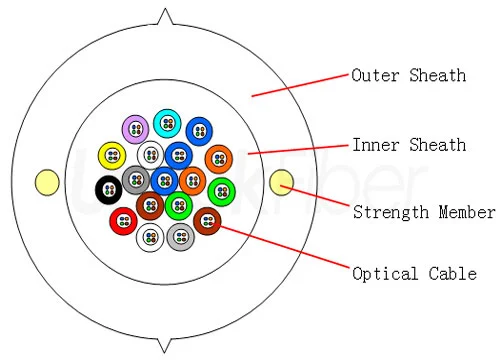

The structure for outdoor fiber optic cables is loose tube as the core container. The structure of indoor fiber optic cables are usually laid in a tight sleeve type. The large cores of indoor fiber optic cables can also be laid in ribbons.

The laying requirements of fiber optic cable : The bending radius of the optical fiber should be at least 15 times the outer diameter of the optical fiber, and at least 20 times during the construction process; when laying the optical cable, the rotation of the optical cable reel should be synchronized with the laying speed, and the speed of the optical cable index is general 15 meters per minute; when laying fiber optic cables, keep a slack arc at the exit of the fiber optic cable, and reserve a buffer margin, but not too much to avoid back buckling of the fiber optic cable; the length of the fiber optic cable reserved at both ends is 5-10 meters ; When laying optical cables, labels should be made and the laying-out records should be filled in; all optical cables should not be exposed.

How to determine the choice of fiber optic core?

The number of fiber optic cable cores is the number of glass fibers contained in each cable. The following editor will introduce some methods to determine the number of fiber cores.

First, clearly know the number of wiring points on the layer, calculate the number of switches, and whether the connections between switches are stacked or not. If stacking, the key switch is dual-system hot standby redundancy, 6 fiber cores are enough.

If you don't need to stack a switch with 4 cores, multiply the number of switches by 4 plus 4 cores for redundancy. (Note: Redundancy: As long as there is more than used, the more redundant is called redundant master/backup: one is used, and the other is exactly the same as backup; hot backup: all in working state at the same time; cold backup: backup equipment is in standby mode.)

Experienced practice: each floor wiring closet (horizontal wiring cabinet), set up an optical fiber, generally six cores: two cores are used, two cores are spare, and two cores are redundant; some use eight core optical fibers. The standard minimum configuration is 2 cores per 48 points. Of course, 4 cores can be selected for 48 points, because 2 cores are the smallest unit of optical fiber, and it is more appropriate to leave 2 cores as a backup.

In addition to the number of fiber cores and fiber types, the selection of optical cables should also be based on the use of optical fibers to choose the outer sheath of the optical fibers. When selecting, pay attention to the following points:

1. When the outdoor fiber optic cable is buried directly, it is better to choose an armored fiber optic cable. When it is overhead, a black PE outer sheathed fiber optic cable with two or more reinforcing ribs can be selected.

2. When selecting optical cables used in buildings, attention should be paid to their flame retardant, toxic and smoke characteristics. Generally, flame retardant and smokey types can be selected in ducts and forced ventilation. Flame retardant should be used in exposed environments. , Smokeless and non-toxic type.

3. For vertical wiring in the building, stranded optical cables can be used; for horizontal wiring, branch optical cables can be used.

4. Multi-mode optical cables can be used for transmission distances within 2km; relay or single-mode optical cables can be used for more than 2km.

The above are just a few issues considered from the application. It needs to be flexibly mastered during implementation. In fact, the wiring environment is complex and diverse, and various problems may arise at any time. This requires us to strictly follow the wiring standards during planning and construction. When we encounter problems, we can analyze them flexibly and we will be successfully resolved.

If you need more information or support on fiber optical products from fiber optic products supplier, please don’t hesitate to contact us sales@unitekfiber.com, we will try our best to support you. We can provide the following products:

Pre-terminated direct burial fiber