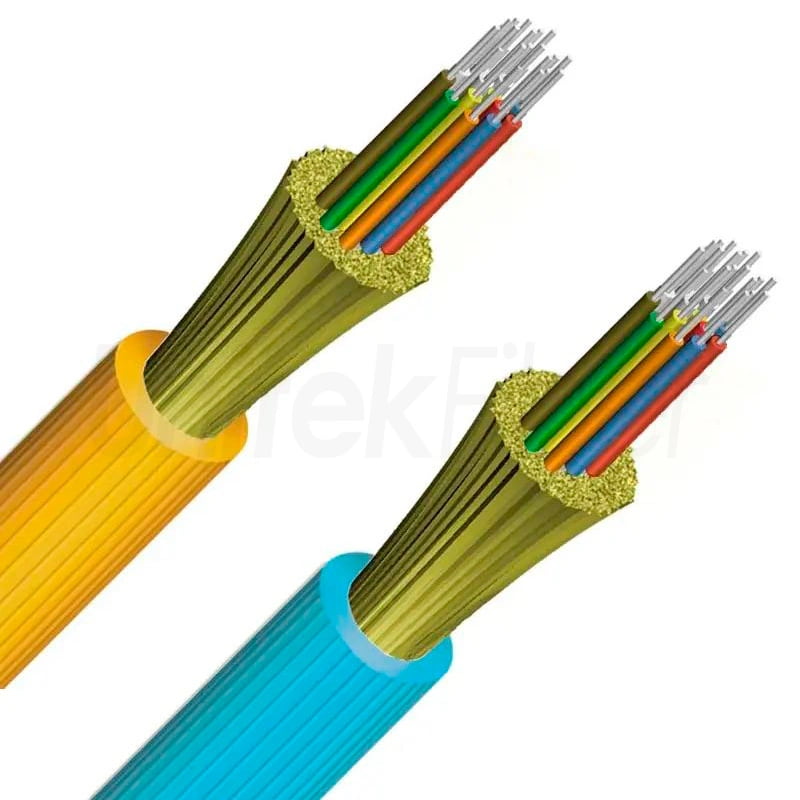

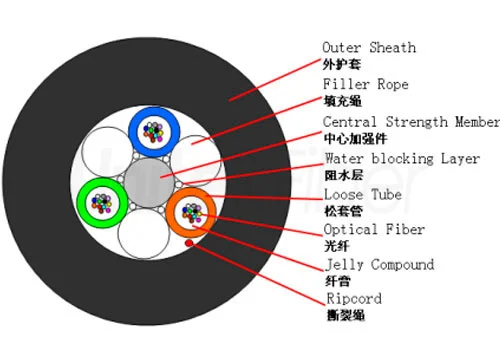

The stranded micro air blown fiber optic cable is mainly composed of outer sheath, fiber paste, cable paste, fiber reinforced composite plastic (FRP). The outer sheath is filled with cable paste.

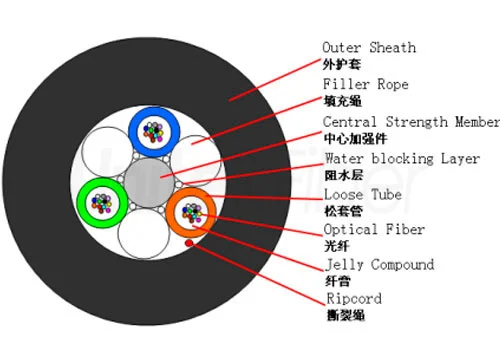

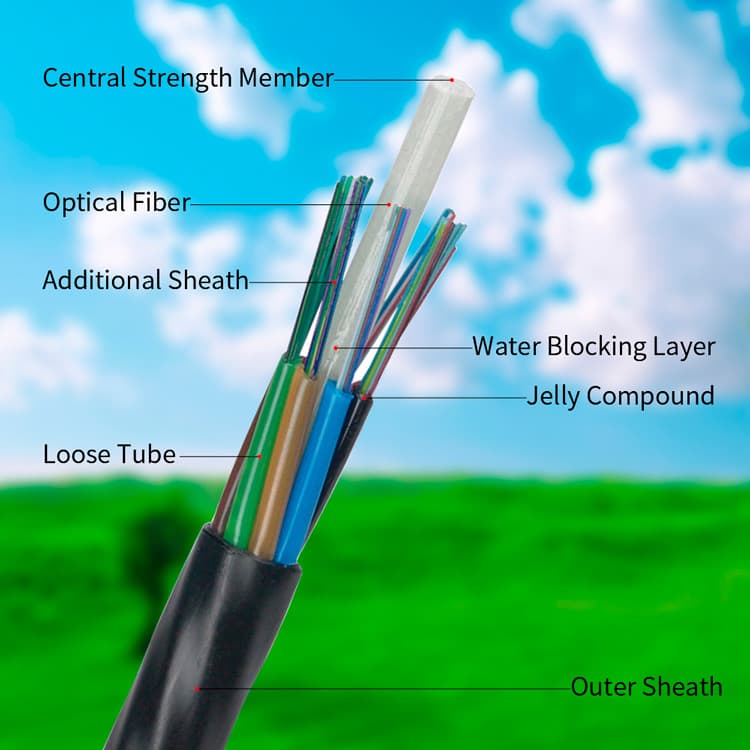

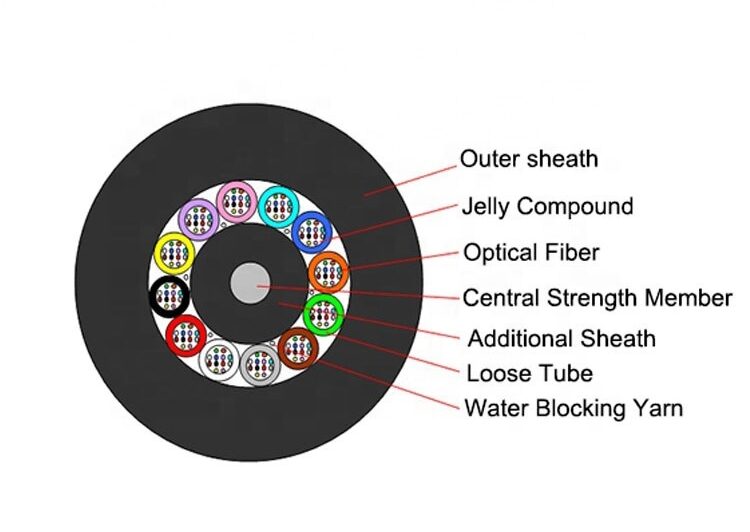

GCYFTY Air Blown micro fiber optic cable is a technology that minimizes the size of optical cables and pipes by optimizing materials, processes and structures, and laying them by air-blowing method to maximize the use of pipe space. Air-blown fiber optic cable (GCYFTY) is a 250μm optical fiber sheathed in a loose tube made of high-modulus material, and the loose tube is filled with a waterproof compound. The center of the cable core is a non-metallic reinforcement core (FRP). The structure requires that the MDPE material cushion may be coated on the outer layer. The sleeve is twisted around the center reinforcement core to form a compact and round cable core, and the gap in the cable core is filled with resistance. Water filled, the outer sheath is extruded into HDPE and then formed into a cable.

The Fiber Cores of GCYFTY Air Blown Fiber Cable is from 2 cores to 288 cores

The air-blown optical cable adopts a non-metallic structure design, which can effectively prevent radio frequency interference and electromagnetic wave interference. The structure design of the optical cable is particularly tight, which effectively prevents the sleeve from retracting. The loose tube material has good hydrolysis resistance and high strength. This kind of fiber optical cable is made of HDPE sheath to meet the air pressure strength during air blowing construction; complete cable core filling measures are used to ensure the waterproof performance of the optical fiber cable. Double-sided corrugated steel tape (PSP) improves the moisture resistance of the optical cable.

GCYFTY fiber optic cable can be used as the drop cable of feeder segments in FTTH networks and can be laid by air blowing to connect the branch point with the access point for subscribers.The type optical fiber cable is also applicable in backbone networks, metropolitan area networks and access networks.

Because air Blown Mini Cable (MINI) is small size, light weight, enhanced surface outer sheath fiber unit designed for blowing into micro tube bundles by air flow.

The Air Blowing Micro fiber Optic Cable is applicable in backbone networks, metropolitan area networks and access networks.

Yes, the air blown fiber cable is composed of a combination of micro tubes (bundles), optical fibers (bundles), and blowing fiber devices.

Air blowing fiber cable can be used as the drop cable of distribution segments in FTTH networks and can be laid by air blowing to connect the branch point with the access point for subscribers.

We provide a wide range of good quality cables from 2–144 fibers with a variety of designs to meet the demands of most installation conditions.

On time delivery and always has great customer service!