In the ever-evolving world of telecommunications, the demand for faster and more reliable internet connectivity continues to rise. To meet these demands, network operators are constantly seeking innovative solutions that can not only improve performance but also enhance the efficiency of their infrastructure. One such solution that has gained significant popularity is air-blown fiber optic cable. In this blog, we will explore how air-blown fiber optic cable utilize ducts efficiently, leading to a more streamlined and cost-effective network deployment.

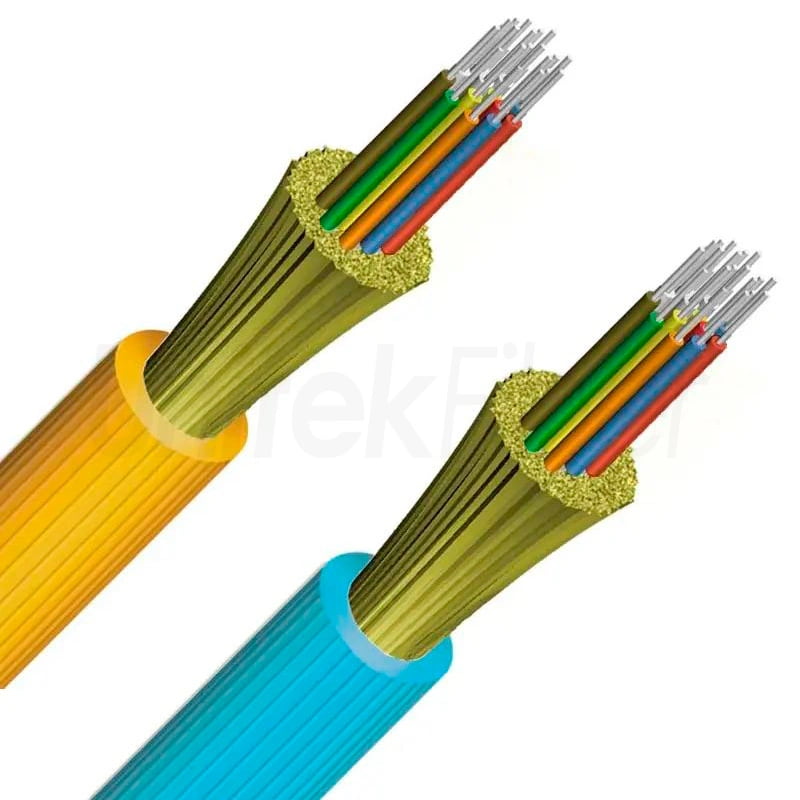

That is, the air blowing method of optical cable is to blow the optical cable into the pre-embedded silicon core tube by means of high-pressure air blowing. The air blowing cable blowing machine blows high-pressure, high-speed compressed air into the silicon core tube, and the high-pressure airflow pushes the air-sealing piston, so that the air-sealing piston connected to the end of the fiber optic cable forms a settable uniform pulling force on the optical cable. At the same time, the hydraulic crawler conveying mechanism of the cable blowing machine clamps the optical cable and transports it forward to form a conveying force. The combination of pulling force and conveying force makes the penetrated optical cable quickly pass through the pipeline in a suspended state along with the high-speed airflow. Communication trunk optical cable pipeline is the development trend.

Air-blown fiber optic cable offer significant cost savings compared to traditional cable systems. By utilizing micro-duct, network operators can significantly reduce the amount of physical infrastructure required, such as trenches or overhead cable trays. The smaller diameter of micro-duct also allows for higher fiber density within the same duct space, maximizing the utilization of available resources.

The flexibility of air-blown fiber optic cable is a game-changer in terms of network scalability. Micro-duct can accommodate multiple fiber units, allowing for easy upgrades or additions without disrupting the entire network. As technology advances and bandwidth demands increase, operators can simply blow in additional fiber units, future-proofing their network infrastructure.

The use of compressed air to blow fiber units into micro-duct significantly speeds up the deployment process. Compared to traditional cable installation methods, which can be time-consuming and labor-intensive, air-blown optical cable can be deployed rapidly, minimizing network downtime and disruptions.

Air-blown fiber optic cable, with their utilization of micro-duct, have revolutionized the way network operators deploy and maintain their fiber networks. By leveraging the efficiency benefits of micro-duct, operators can reduce deployment costs, improve scalability, and streamline maintenance activities. As the demand for high-speed connectivity continues to grow, air-blown fiber optic cable are undoubtedly a valuable solution in maximizing efficiency and ensuring a cost-effective network infrastructure.

As a leading fibre optic products supplier, UnitekFiber is dedicated to providing high quality fiber optic cable that meet your specific requirements including OSP fiber cable, ADSS cable, Direct bury fiber optic cable, Aerial fiber cable, MTP MPO fiber breakout cable, etc. For more detailed information, please visit our website at www.unitekfiber.com. We look forward to supporting you with our reliable and efficient fiber optic solutions.