Equip yourself with the knowledge to choose the right fiber joint closure for any application. In this guide, we uncover the essential strategies for enhancing your fiber networks' longevity and efficiency.

Sealing methods for fiber optic splice closures are critical for the following reasons.

First, it protects against environmental hazards such as moisture, dust, and debris that can damage delicate fiber optic cables. Effective sealing ensures the longevity and reliability of the network.

In addition, properly sealed fiber junction box maintain optimal signal performance and avoid foreign elements that can cause signal loss or attenuation, resulting in poor network performance or complete failure. As a result, these methods ensure the integrity and efficiency of the fiber optic system.

By blocking the ingress of water and other contaminants, sealing methods can significantly reduce the risk of electrical hazards and short circuits, thereby improving the overall safety of the network.

Investing in a robust sealing method for fiber splice enclosure is a surefire way to ensure a secure, reliable, and high-performance fiber optic network. It protects the cable from external threats while maintaining signal integrity and system safety.

Heat-shrink fiber optic splice closure uses a material that shrinks when heated to form a tight seal around the fiber optic cable, protecting the splice point from moisture, dust, and mechanical damage. This method is known for its durability and resistance to adverse weather conditions and is generally reliable.

Reliability: It provides a reliable sealing solution that maintains a secure grip for a long time.

Waterproof: It guarantees a waterproof seal to prevent moisture and potential water damage.

Easy to install: The installation process is relatively simple and only requires basic training for technicians.

Cost-effectiveness: The manufacturing cost is low compared to mechanical fiber closures.

Limited adjust-ability: Once sealed, it is difficult to access the fiber optic cable for adjustment or maintenance.

Time durability: The material becomes brittle over time and cracks may appear.

High maintenance cost: Expanding fiber capacity requires removing and reinstalling the original splice closure, which increases costs and construction time.

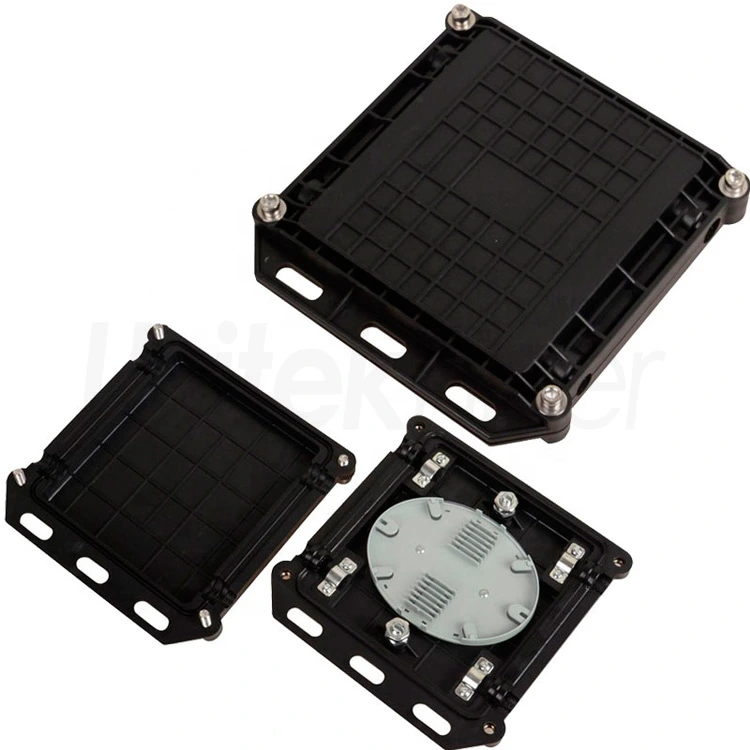

Mechanical joint closure uses physical methods to securely fasten the closure housing using components such as clamps or screws. This method creates a barrier to environmental factors and protects the joint from external influences.

Ideal deployment locations for heat-shrinkable fiber splice case is almost in centralized data centers and underground networks. The environments of centralized data centers is housing centralized data systems where cables are seldom manipulated. With the airtight and watertight sealing make the heat-shrinkable splice box ideal for underground installations.

Skill Requirement: Installation demands skilled professionals, making it suitable for settings with available skilled teams.

Static Environments: Best utilized in environments with minimal adjustments and maintenance needs.

Mechanical sealing fiber splice closure is a viable option in segments requiring a user-friendly setup. And suitable for aerial installations due to its re-enterable feature, accommodating different cable types and facilitating easier maintenance.

The mechanical sealing fiber splice enclosure is also using in diverse outside plant environment, which could be offer needed versatility to house both spliced and pre-terminated cabling solutions in varied network environments. Accommodates installation crews with less specialized skills, apt for broader network segments with a mix of expertise levels.

Selecting the correct sealing method requires consideration of factors such as installation conditions, anticipated environmental challenges, and the specific requirements of the optical splice closure. Therefore, careful evaluation is critical to maintaining the integrity and life of your optic splice enclosure, ensuring optimal performance and protecting your network infrastructure.

UnitekFiber as a professional fiber optic splice closure manufacture, we offer all kindly of fiber splice box as you request, such as horizontal and vertical fiber splice closure with different sealing method. If you need any support, please kindly contact us at sales@unitekfiber.com.