As one of the most important parameters of the optical transceiver modules, the working temperature can affect other parameters of the optical transceiver modules. When the ambient temperature of the optical transceiver modules application changes, its operating current and other parameters will also change accordingly, thus affecting its normal transmission. The extended-grade and industrial-grade optical transceiver modules are products developed to solve this problem.

The optical transceiver meet the industrial temperature standard

Hardware up to standard

The chips and lasers used in industrial-grade optical transceiver modules must use products with an industrial-grade temperature rating, and high-temperature heating is required during testing.

Temperature compensation

When the industrial-grade optical transceiver modules operates at sub-zero low temperature, in order to ensure the stable transmission power of the optical transceiver modules, it must be temperature compensated to ensure its normal operation at low temperature.

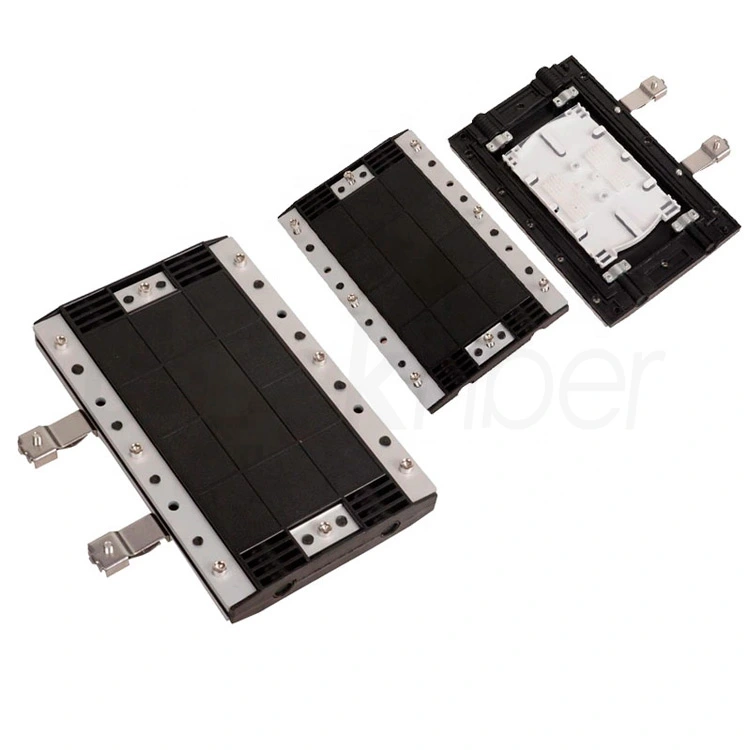

Physical cooling

Industrial-grade optical transceiver modules must have self-cooling function in order to meet the stable operation in high temperature. The heat dissipation silica gel is mainly used for physical cooling so that the heat generated by the laser can be dissipated as soon as possible.