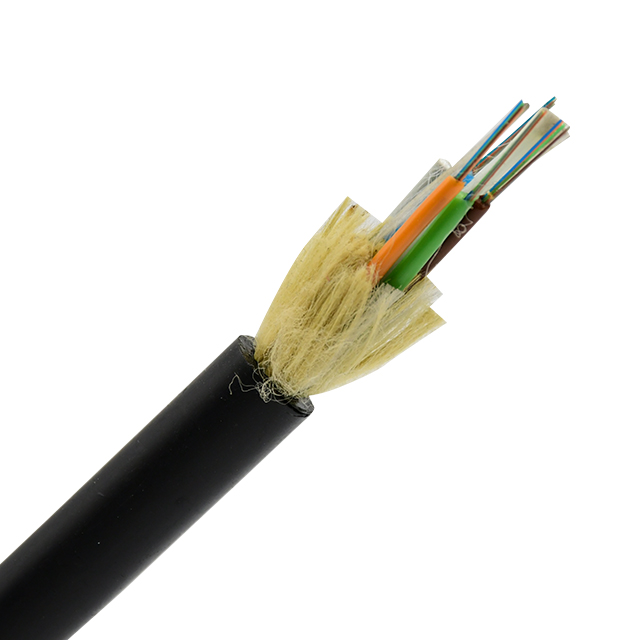

1. Central tube structure ADSS cable

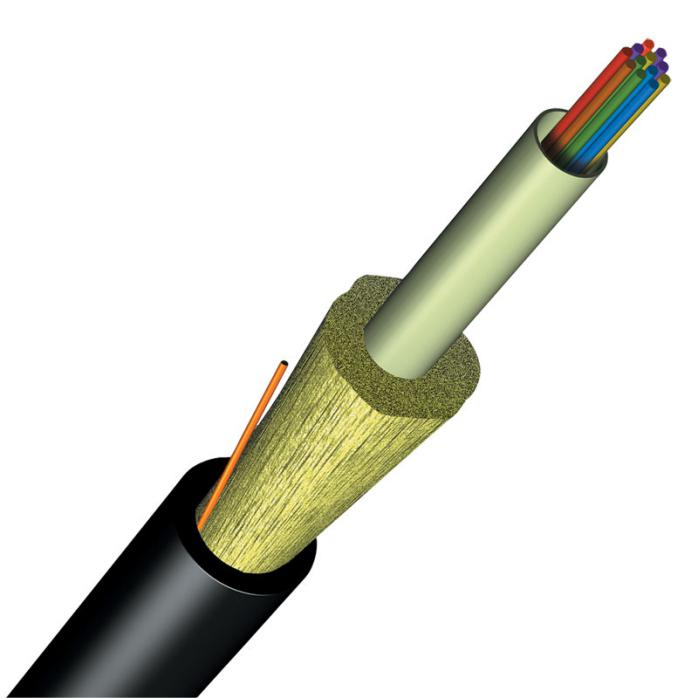

In this structure of the ADSS optical cable, the optical fibers are placed in a PBT tube filled with water-blocking ointment with a certain excess length, and at the same time, a suitable spun yarn is wrapped according to the required tensile strength, and then extruded PE (≤110KV electric field strength) or AT (≥100KV electric field strength) sheath.

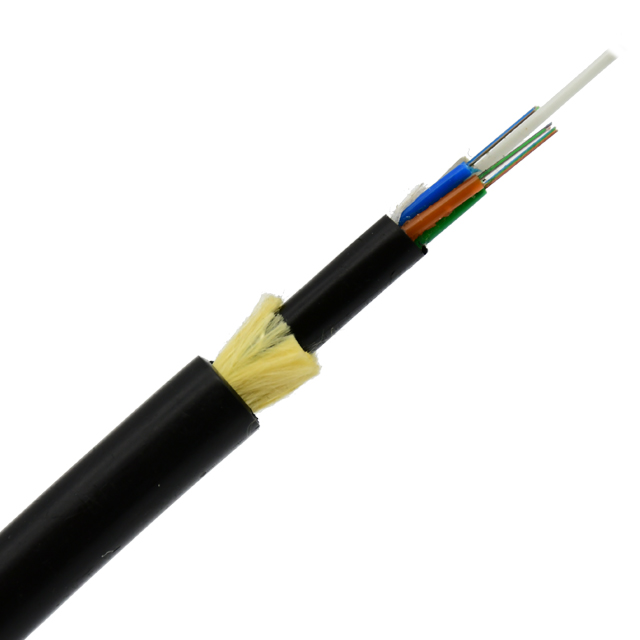

2. Layered twist structure ADSS cable

The layer-stranded structure ADSS cable is that the inner optical fiber and water-blocking grease are added into optical fiber loose tube at the same time, and then different loose tubes are wound around the central reinforcement (usually FRP). It also needs to be wrapped according to the requirements. The Kevlar yarn is finally extruded with PE or AT sheath. According to the environment condistion of ADSS cable laying, the cable ADSS can be produced with single layer of PE or AT sheath or double layers PE or AT sheath.

a. The single jacket ADSS-S optical cable is a type of fiber optic cable used for aerial installations. It consists of a single layer of protective jacketing material, typically made of polyethylene (PE). The single jacket provides basic protection against environmental factors such as moisture, UV radiation, and temperature variations. The single jacket ADSS-S cable is commonly used in short to medium span applications.

b. The double jacket ADSS-D optical cable is an enhanced version of the single jacket ADSS-S optical cable. The double jacket provides extra protection against mechanical stresses, such as tension and compression, that may occur during installation or due to environmental factors. This makes the ADSS-D cable more suitable for long span applications, where the cable may be subjected to higher loads and greater mechanical stresses.

This structure of the ADSS optical cable loose tube and the central reinforcing member filled with grease is fully twisted together to ensure its waterproof performance, and according to different requirements, there are a variety of measures to resist lateral pressure.

Compared with two different structures of ADSS optical cables, the advantages of the central tube structure ADSS cable are: small diameter, light weight, good waterproof performance, low price, and easy installation. The layer-stranded structure has more laying methods, which are suitable for various occasions such as overhead, direct buried, pipeline, and underwater. The remaining length can be controlled easily and the number of fiber cores is more, but the price is also more expensive.

If you neen more information or support on fiber optical products from reliable ADSS cable supplier Unitekfiber, please don't hesitate to contact us sales@unitekfiber.com, we will try our best to support you.