In the communication industry, both ADSS fiber cable and OPGW fiber cable have been fully used. Both need to be able to be used for a long time, so the quality of the fiber cable material needs to be better.

1. The difference between ADSS fiber cable and OPGW fiber cable in structure.

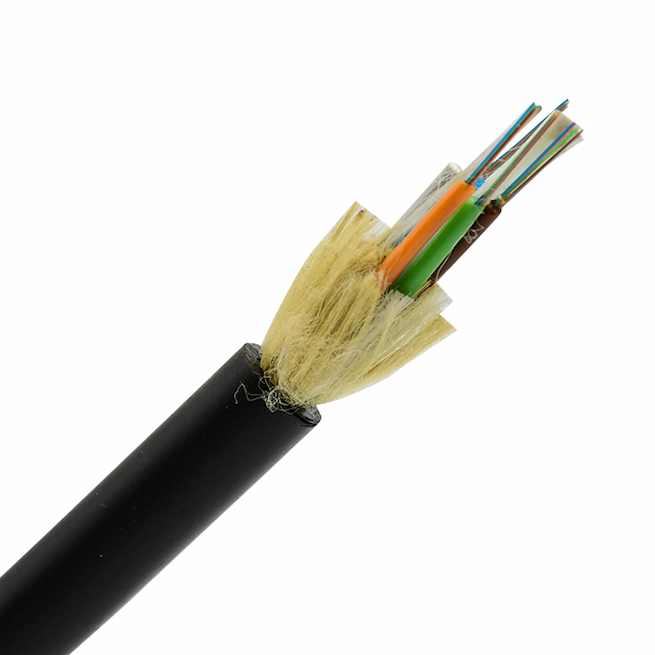

OPGW fiber optic cable is mainly composed of a cable core (optical fiber unit) containing fiber optic cable and metal strands (including aluminum-clad steel wires, galvanized steel wires, aluminum alloy wires, and hard aluminum wires).

ADSS fiber optic cable is mainly composed of cable core, strength member, and outer sheath. The various structures of ADSS fiber optic cables can be summarized into two representative structures. Mainly center beam tube type, layer stranding type.

2. The difference between ADSS fiber cable and OPGW fiber cable in technical parameters.

Rated Tensile Strength (RTS)

Also known as tensile strength or breaking force, it refers to the calculated value of the sum of the strength of the load-bearing section (ADSS mainly calculates aramid fiber). RTS is an important parameter for the configuration of fittings (especially tension clamps) and the calculation and control of safety factor.

Maximum Tensile Strength (MAT)

According to the designed meteorological condition theory, calculate the maximum tension that OPGW fiber optic cable and ADSS fiber optic cable bear. MAT is an important basis for the calculation and control of sag, tension, span, and safety factor.

Daily Average Running Tension (EDS)

Also known as the annual average working tension, it is the average tension generated by OPGW and ADSS during the long-term working process.