When choosing a fiber patch cord, there are several factors that you should consider:

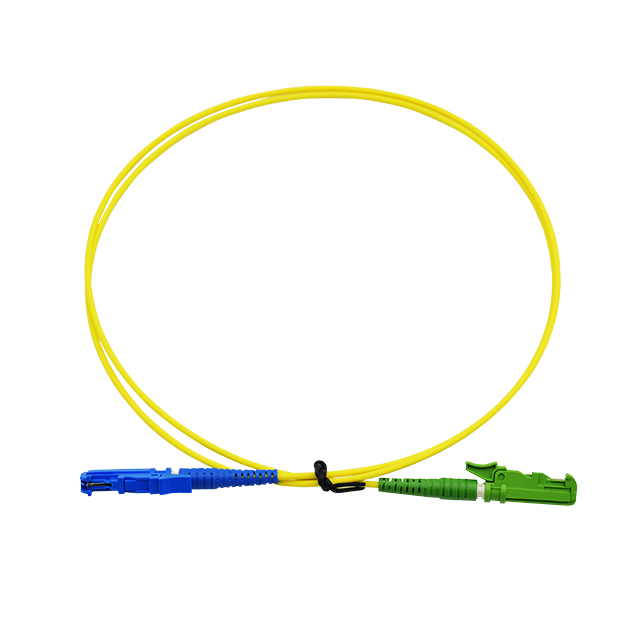

1. Connector Type: The connector type of the patch cord should match the connector type of your equipment, such as LC, SC, FC, ST, or MTRJ. Ensure you choose the correct connector type.

2. Fiber Type: There are two main types of fiber used in patch cords: single-mode and multimode. Single-mode fiber is ideal for long-distance transmission, while multimode fiber is suitable for short-distance transmission within a building or data center.

3. Cable Jacket: Fiber optic patch cords are available with various jacket types, such as PVC, LSZH, and OFNP. PVC is the most common jacket material used in patch cords, while LSZH cables are suitable for areas with high-risk fire hazards. OFNP cables are designed for plenum spaces, which are air-handling spaces in buildings.

4. Cable Length: The length of the fiber optic patch cord should be long enough to connect your equipment but not too long to cause extra cable to wind up.

5. Connector Polishing: Check the end face of the connector to see if it’s polished correctly. A quality end face ensures low-loss connection.

6. Brand Reputation: Choose fiber optic patch cords from reputable manufacturers to ensure the quality of the product.

Unitekfiber is one of the professional fiber cable manufacturers for fiber optic productions, we can supply you with high quality single mode, multimode, simplex, duplex, etc, ..fiber optic patch cord. See www.unitekfiber.com for details or email sales@unitekfiber.com for support.