In the world of fiber optic cable, two commonly used variations for indoor installations are tight optic fiber and loose optic fiber optical cable. These variations differ in their construction and characteristics, making them suitable for different applications and environments. In this article, we will explore the difference between tight and loose optic fiber for indoor optical cable, helping you understand their unique features and guiding you towards choosing the right option for your specific needs.

Tight Fiber Cable:

Construction

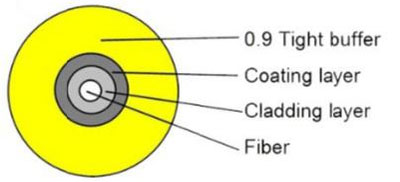

Tight fiber optic cable, also known as tight-buffered optical cable, are designed with individual optic fiber that have a protective coating or buffer tightly applied around each fiber. The tight buffer provides physical protection to the optic fiber, making it more robust and resistant to external forces.

Size and Flexibility

Tight fiber optic cable have a smaller outer diameter compared to loose fiber optic cable, making them more compact and easier to handle during installation or routing in confined spaces. The tight buffer also enhances the flexibility of the optical cable, allowing it to be bent and maneuvered without compromising the integrity of the optic fiber.

Mechanical Protection

The tight buffer acts as a primary mechanical protection layer for the individual optic fiber, shielding them from potential damage due to bending, twisting, or other physical stresses. This makes tight fiber optic cable ideal for situations where additional ruggedness is required, such as in areas with higher foot traffic or for applications that involve frequent movement or handling.

Loose Fiber Optic Cable:

Construction

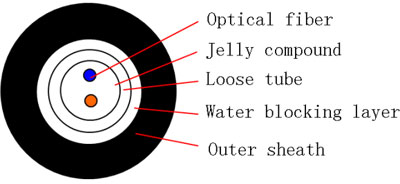

Loose fiber optic cable consist of individual fibers that are not enclosed in a tight buffer. Instead, they are bundled together within a common outer jacket. The optic fiber have more freedom of movement within the optical cable structure.

Air Circulation and Cooling

One advantage of loose fiber optic cable is that they allow for better air circulation and heat dissipation between the optic fiber. This is especially important in high-density installations or environments where heat buildup might occur. The presence of air gaps between the optic fiber enables efficient cooling, minimizing the risk of signal degradation due to excessive heat.

Ease of Termination and Splicing

Loose fiber optic cable are typically easier to terminate and splice compared to tight fiber optic cable. The loose optic fiber can be easily accessed for termination or fusion splicing, simplifying the installation process and reducing the time required for connectivity.

Conclusion

Understanding the difference between tight and loose fiber optic cable for indoor installations is essential for selecting the most suitable option for your specific needs. Whether the focus is on mechanical protection, flexibility, heat dissipation, or ease of termination, considering the factors discussed will help you make an informed decision. By choosing the right fiber optic cable, you ensure optimal performance, reliability, and longevity of your indoor fiber optic network.

UnitekFiber is dedicated to providing high quality fiber optic cable that meet your specific requirements. For more detailed information, please visit our website at www.unitekfiber.com. We look forward to supporting you with our reliable and efficient fiber optic solutions.