With the acceleration of the FTTH construction process, the fiber optic cable infrastructure is becoming increasingly sophisticated. However, the rapid growth of traffic and the accelerated pace of 5G commercialization have led to increasing demand for network capacity. In order to increase the capacity of the network, the number of fiber cores needs to be increased. At the same time, urban land resources are increasingly scarce and urban pipeline resources are becoming more and more tight. Therefore, it is particularly important to increase the number of optical fiber cores in a limited pipeline while increasing the optical fiber assembly density and reducing the diameter and weight of optical cable. In this context, the use of air-blown micro fiber cables becomes necessary.

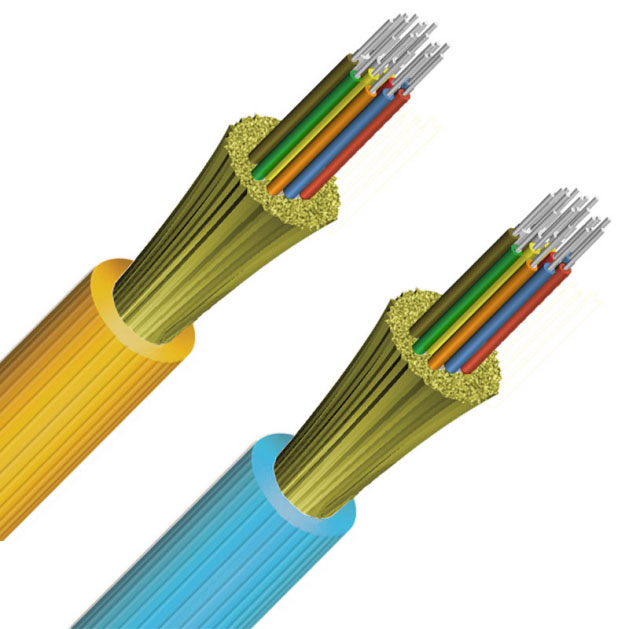

Air-blown micro fiber cables are important components in the access network, and their main function is to transmit information. Compared with traditional optical cables, the advantages of air-blown micro fiber cables are more obvious. The amount of materials and processing costs for the same number of micro-cables are greatly reduced, the structure size is small, light weight, high fiber installation density, good weather resistance, and good bending performance. Air-blown micro cable is suitable for overhead and pipeline laying. In addition, it can be directly installed in the existing optical cable pipeline, which can effectively save pipeline resources and meet the needs of network expansion and construction. Air blowing micro fiber cables have good overall performance and are superior to traditional optical laying methods, which have attracted more and more attention from operators.

From the perspective of the international market, air-blown micro fiber cables have been widely promoted in the international market with their excellent comprehensive performance and unique laying methods, and have been widely used in long-distance trunk lines and metropolitan areas in the United States, Germany, France, the Netherlands, Denmark and other countries. In the network and access network, in most Nordic countries, whether it is the backbone layer or the access layer, 70% of optical cables are constructed by air blowing, and 60% of them are using air blowing micro cables.

If you neen more information or support on fiber optical products, please don't hesitate to contact us sales@unitekfiber.com, we will try our best to support you.