In the realm of fiber optical cable installation, the question of whether All-Dielectric Self-Supporting (ADSS cable) can be installed underground is an important one. Let's delve into this topic and explore the various aspects involved.

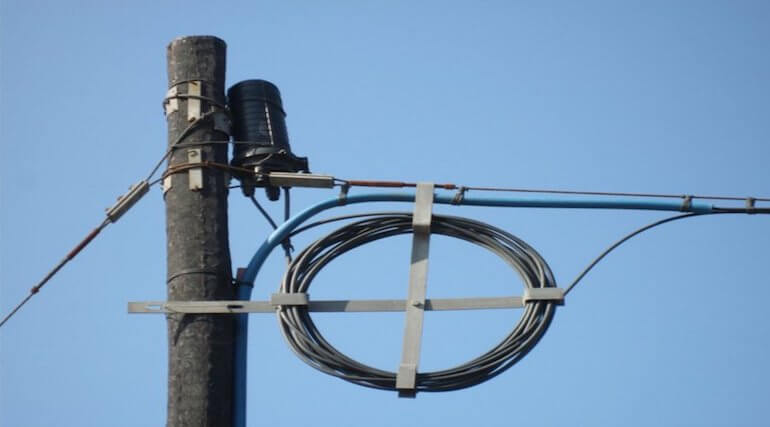

ADSS fiber optic cable is designed to be self-supporting and are commonly used in overhead power line installations. They are constructed with a dielectric (non-conductive) material, which allows them to be installed without the need for a separate metallic support structure, such as a messenger wire. This makes them a popular choice for applications where it is desirable to avoid the use of conductive materials that could potentially cause interference or safety issues.

---Pros

Reduced Exposure to Environmental Hazards: Installing ADSS fiber optical cable underground can protect them from exposure to extreme weather conditions such as strong winds, ice storms, and lightning strikes. This can potentially increase the cable's lifespan and reliability, as it is less likely to be damaged by these external factors.

Aesthetic Appeal: In some urban or residential areas, underground installation may be preferred for aesthetic reasons. Aerial fiber optic cable can sometimes be seen as an eyesore, and burying them can help to improve the visual appearance of the environment.

Lower Risk of Physical Damage: Underground cables are less vulnerable to accidental damage caused by vehicles, construction activities, or tree branches falling. This can reduce the frequency of maintenance and repair work, saving both time and money in the long run.

---Cons

Installation Complexity and Cost: Installing aerial fiber optic cable underground is generally more complex and costly than overhead installation. It requires excavation work, which can be time-consuming and expensive, especially in areas with hard soil or rocky terrain. Additionally, proper conduit systems need to be installed to protect the cable from moisture, rodents, and other underground hazards, further increasing the installation cost.

Difficulties in Maintenance and Repair: If an underground ADSS OFC develops a fault, it can be much more difficult to locate and repair compared to an Aerial cable. Locating the exact point of the fault may require specialized equipment and techniques, such as cable fault locators and underground cable tracing tools. The repair process may also involve digging up the cable, which can disrupt the surrounding area and cause additional inconvenience.

Moisture and Corrosion Risks: Underground environments are often more humid and prone to corrosion compared to the air above ground. ADSS cable installed underground need to be properly protected against moisture ingress and corrosion to ensure their long-term performance. This may require the use of special cable coatings or encapsulation materials, which can add to the overall cost and complexity of the installation.

If it is decided that underground installation of ADSS optical cable is the best option, there are several important considerations to keep in mind:

Cable Selection

Not all ADSS cables are suitable for underground installation. Some fiber optic cable may have better moisture resistance and corrosion protection features than others. It is essential to select a fiber optical cable that is specifically designed or rated for underground use and that meets the relevant industry standards and specifications.

Installation Standards and Practices

Proper installation techniques and standards must be followed to ensure the successful underground installation of ADSS fiber optic cable. This includes correct excavation depth, proper bedding and back-filling of the fiber optical cable, and the use of appropriate conduit materials and installation methods. It is also important to ensure that the cable is installed in a way that allows for future maintenance and repair access.

Environmental Impact Assessment

Before proceeding with underground installation, an environmental impact assessment may be required, especially in sensitive areas. This assessment helps to identify any potential impacts on the local ecosystem, such as disruption to soil structure, displacement of wildlife, or interference with underground water tables. Measures can then be taken to minimize these impacts and ensure that the installation is carried out in an environmentally responsible manner.

While ADSS cables are primarily designed for overhead installations, they can be installed underground under certain circumstances. Before making a decision, it is crucial to carefully evaluate the specific requirements and conditions of the project and weigh the pros and cons of both overhead and underground installation options. By doing so, it is possible to make an informed choice that will ensure the reliable and efficient operation of the optical fiber network while also taking into account factors such as cost, environmental impact, and long-term performance.

UnitekFiber as a profesional ADSS cable manufacturer, we offer all kind of ADSS fiber optic cable to support your business, such as single jacket ADSS cable, double jacket ADSS cable or etc. For any inquiries or further information, please don't hesitate to reach out to us at sales@unitekfiber.com.