Due to the special environment of indoor applications, indoor fiber cables must meet the requirements of international standards for toxicity, corrosivity and low smoke while maintaining excellent flame retardancy, mechanical properties and optical transmission characteristics. The rise of fiber cables between floors in vertical systems, narrow space applications of communication cabinets in horizontal systems, fiber-to-desktop applications, and communication applications passing through high-pressure air-filled spaces all place different requirements on indoor fiber cables. How to choose the right fiber optic cable to meet the needs of different indoor applications?

Indoor Fiber Cable Should Choose Tight-buffered Optic Fiber

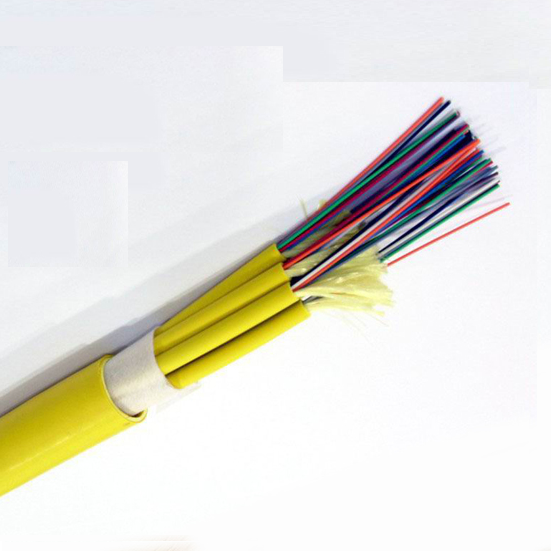

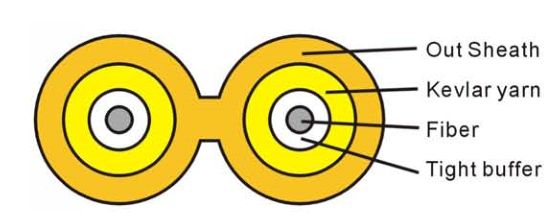

At present, most indoor fiber cables use tight-buffered optical fibers or single-core cables as basic units, reinforced by aramid yarns, and soft optical cables with flame-retardant or non-flammable sheaths. There are also plastic optical fibers as indoor wiring fiber cables, but this product has not yet been widely used.

The tight-buffered fiber is integrated with the fiber to provide good mechanical protection, so that the fiber exhibits good compression and bending resistance when it is terminated. In addition, The tight-buffered fiber is of good flexibility and toughness,small bending radius and excellent moisture-proof function.

The good environmental protection of tight-buffered fiber can improve the service life of the fiber. The tight-buffered fiber is compatible with all standard connectors and simplifies the termination procedure and reduces the termination cost. Moreover, the tight buffer layer is easily stripped to the fiber core.

Compared with the loose tube design, the loose tube uses jelly to buffer and moisture-proof the optical fiber, while the jelly does not have fire resistance. This is far from meeting indoor fire safety requirements. Moreover, the flame spreads along the optical cable, so that the damage of the optical cable extends to the depth of the wall and deep into the pipe. During installation, a lot of cleaning materials are needed and a lot of cleaning time is spent on ointment. At the same time, a connection method is needed, which greatly increases the cost of materials. The tight-buffered optical fiber design of flame-retardant or non-flammable sheath of the indoor optical cable make the indoor optical cable fully meet the requirements of indoor safety applications.

The outer protective materials used for indoor fiber cables include PE, PVC, polyurethane, low-smoke halogen-free materials, flame-retardant PE, etc. Indoor fiber cables with different outer protective materials can be used in environments with different requirements. Therefore, indoor high-performance communication transmission applications generally use indoor fiber cables designed with tight-buffered optical fibers.

Selection and Application of Indoor Fiber Cable

Vertical Lifting Cable(riser)

After the fiber cable enters the building, it is necessary to provide the connection between the entrance equipment, equipment room or computer room and the communication cabinets on different floors, which is called "vertical wiring system". At this time, the wiring fiber cables are mostly located in the riser in the vertical shaft between the floors. For this reason, the fiber cable needs to withstand greater tensile force (self-weight maximum).

Simplex and Duplex interconnection indoor fiber cable

Simplex tight sleeve indoor fiber cable , Duplex figure 8 tight sleeve indoor fiber cable, tight sleeve 2 core ~ 4 core circular structure indoor fiber cable adopts the flexible tight sleeve structure and high load-bearing aramid yarn surrounding the tight sleeve fiber, so the cable structure size is small and the cable is flexible, which make the indoor fiber cable withstand a small bending radius and no traces of inventory. They are idea choices of interconnection fiber cable of fiber to the workstation, plug-in wiring, pigtails, jumpers in the communication cabinet, the communication cabinet to the lead-out end of the indoor wall, and the lead-out end to the transceiver application.

They are directly equipped with standard connectors, which play the role of interconnection between optical end equipment and backbone (vertical) optical cables in communication cabinets, distribution boxes, protective boxes, and equipment boxes. This type of optical cable is convenient and easy to install in a limited space, and becomes an ideal network cable solution for wiring in a limited space and plugging in a flexible cord in a building.

Fiber Cable For Inflatable Environment (Plenum)

In indoor applications, when optical cables need to pass through conveying pipes, high-pressure air-filled spaces or air handling systems to transmit information, Plenum-level indoor fiber cables are required. This special environment puts forward stricter requirements on the flame retardancy and corrosion resistance of the fiber optic cable. Therefore, the tight sleeve material and outer sheath material of the indoor fiber cable used are more stringent. The sleeve is made of PVC material, and the outer sheath material is of a flame retardant PVC material or hard fluoropolymer that meets the UL certification. The PVC design is superior to fluoropolymers. Because PVC is soft and easy to bend, there is no trace of inventory, and it can be stored in a ring.

If you need more information or support on fiber optical products, please don’t hesitate to contact us sales@unitekfiber.com, we will try our best to support you.