Optical fiber communication has become an important part of power grid construction and power grid transformation. The optical fiber communication capacity is large, and the anti-interference performance is good, which can not only meet the needs of communication and automation in the power system, but also provide the excess capacity to the society. Optical fiber communication can not only improve the power supply reliability of the power grid, but also achieve good economic benefits.

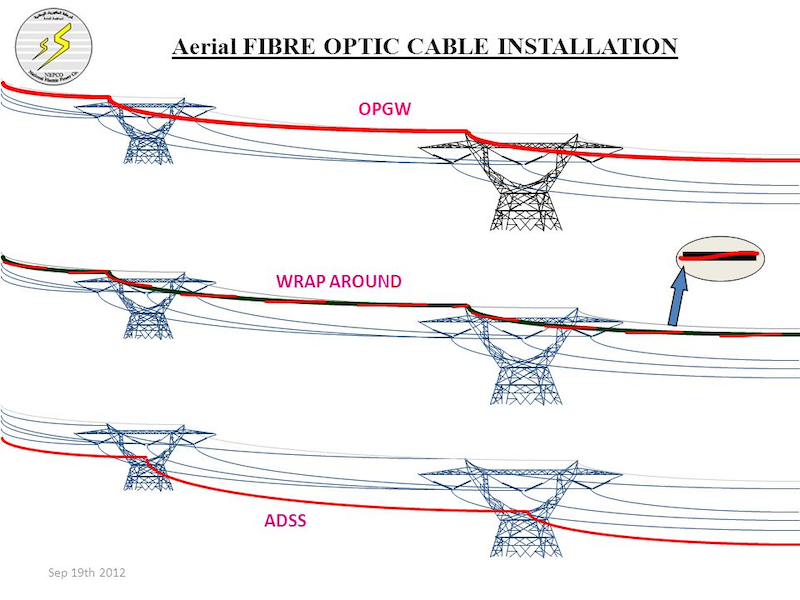

It is a very economical way of laying optical cables by using aerial power line corridors to overheand laying on line pole . At present, there are two main forms of laying optical cables on overhead transmission lines: optical fiber composite overhead ground wire (OPGW) and all-dielectric self-supporting optical cable (ADSS cable). OPGW is usually selected for new power lines, and ADSS is often used for power lines that have already been built. ADSS fiber optic cable has a smaller investment than OPGW, can be overhead laying in the state of no blackout of power lines, and is more convenient for design, construction, maintenance, etc. It has been widely used in completed power lines.

The application scope of ADSS fiber optical cable

For newly built or completed high-voltage transmission lines of 220 kV and above, which are used as communication trunk corridors, the engineering personnel should choose OPGW from the aspects of reliability, construction and maintenance of optical fiber communication to ensure the matching of the operating life (more than 30 years) of the communication line and the transmission line. ADSS optical cables should not be used for main line transmission lines of 220kV and above.

For the completed transmission lines of 220kV and below, especially the communication between regional substations, ADSS fiber optical cable can be considered. Engineers should first consider the reliability of installing ADSS fiber optical cables on aerial power lines, and evaluate the elapsed time of the power lines, the aging degree of the wire pole, and the original design standards to determine the feasibility of the installation.

Since the design and technical regulations of power lines have been modified, adjusted and supplemented over the years, it is difficult to check the strength of power line poles that have been in operation for many years, which has become a key issue in the installation of ADSS fiber optical cables. The general principle is that the ADSS fiber optical cable can be aerial laying without affecting the safe operation of the power line or reducing reliability. Therefore, the author recommends laying ADSS fiber optical cable, and the power line with better conditions should be selected as much as possible.

The Selection of ADSS Fiber Optical Cable

1.The Structure of ADSS fiber optical cable

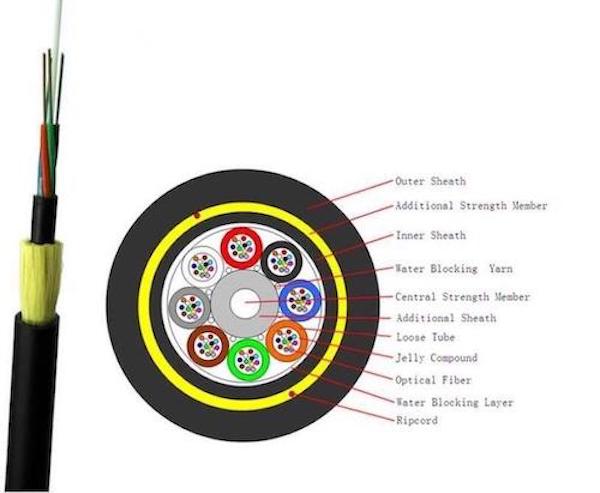

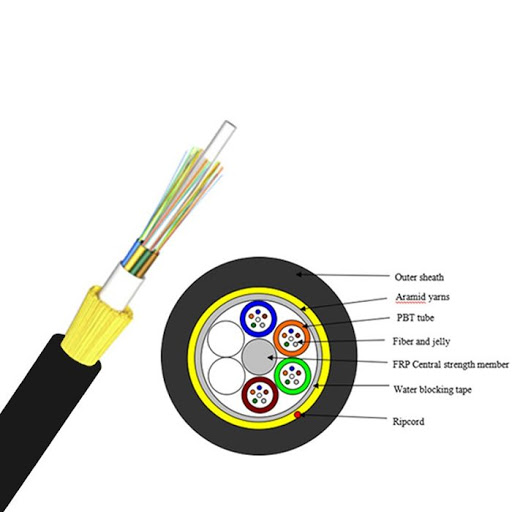

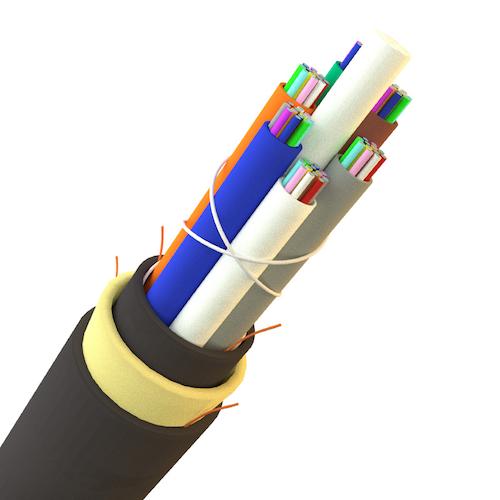

The structure of the ADSS fiber optical cable is divided into two categories: central loose tube and multi-stranded tube. Except for some power lines with good conditions in all aspects, it is generally appropriate to use the multi-stranded tube structure of the ADSS fiber optical cable.

The optical fiberglass in the ADSS fiber optical cable is guided into the loose tube in a wave shape, and then the loose tube is twisted to produce a twisted excess length. The optical fiber has an appropriate excess length, which ensures that the optical fiber is not stressed when the optical cable is subjected to the mechanical load of normal operation (that is, the fiber is zero Tension design), will not increase the loss of fiber.

2. The electrical performance

ADSS Fiber cable

The selection of the ADSS fiber optical cable must first consider the electrical performance requirements, that is, the size of the space induced electric field (potential) that the ADSS can withstand. The reason is that the ADSS optical cable works near the high-voltage line conductor, and there is an electromagnetic field in the space around the conductor. The capacitive coupling between the wire and the ground makes the optical cable in a space potential position. When fog, dew or light rain, the moisture pollution forms a resistance layer on the surface of the outer jacket of the optical cable. Under the effect of space potential, a current flows between the surface of the sheath and the ground cable of the optical cable on the iron tower. The current heating causes the water to evaporate, which forms a small dry zone on the surface of the outer sheath of the optical cable, blocking the current. When the potential difference reaches a certain height, the discharge will form an arc, which is the dry-band arc. It generates heat which can cause the cross-linked polymer to gradually lose its binding force and form corrosion, and the sheath will melt into holes. This phenomenon or fault is called sheath electric corrosion or electrical traces, which can lead to cable breakage in severe cases.

The type of outer sheath used by ADSS depends on the size of the spatial potential of the installation position of the optical cable and is related to many factors such as the voltage level of the power line, the structure of the line pole, the arrangement of the conductor and the phase arrangement.

3. The mechanical properties of ADSS Fiber Optic Cable

(1) Mechanical properties of ADSS Fiber Optical Cable

In terms of the mechanical strength of the ADSS fiber optical cable, kevlar carring and the number of kevlar in the cable determine the rated tensile strength (RTS) of the optical cable in kN.

The maximum allowable tensile (stress) force (MAT) of the ADSS fiber optical cable corresponds to the maximum tensile (stress) force on the optical cable under the worst design meteorological conditions. The unit is kN or N/mm2.

The annual (day) average tensile (stress) force (EDS) of the ADSS fiber optical cable corresponds to the tensile (stress) force in the absence of wind, ice and annual average temperature, and the unit is kN or N/mm2.

The ultimate operating tension (UOS) of the ADSS fiber optical cable can be regarded as the overload capacity of the cable, which corresponds to the tensile (stress) force the cable bears when the design meteorological load is exceeded for a short time, the unit is kN or N/mm2.

There is a certain relationship between these four force values and is related to the structure of the optical cable. The relationship between them is also called the "fiber strain window" or the "stress-strain" performance of the cable.

(2) Tension-sag characteristics

The mechanical properties of the fiber optical cable related to this characteristic mainly include cable diameter, cable weight, elastic modulus and thermal expansion coefficient.

ADSS fiber optical cable has variable span characteristics. For the same optical cable, if the meteorological conditions and sags are different, its allowable range is different.

According to the design meteorological conditions, distances, spans of the power line to be erected, the design and operating conditions of the tower, the line angle, and the height difference, etc., the engineering personnel determine the mechanical properties of the ADSS optical cable. Engineers usually use the ADSS cable tension sag table calculated by the design meteorological conditions of the power line as the basis to check the strength of the tower. The added loads of ADSS fiber cable mainly include wind load, re-icing load and unbalanced tension and aross-crossing should also be checked. Finally determine the mechanical properties of the ADSS optical cable itself.

4.Determination of control conditions

Determination of Control conditions (electrical or mechanical properties of ADSS fiber optical cable) is an important part of ADSS installation design, which is related to the safe operation of the line and the service life of the optical cable. It is not only related to the operating conditions of the power lines and meteorological conditions, but also related to the mechanical properties of the ADSS itself. It affects the selection of ADSS type, ADSS suspension position determination (electrical performance), ADSS tension and sag (mechanical performance) required for crossover and line pole load.

(1) Line pole conditions and spatial potential distribution

Line pole conditions mainly include: pole model and size, system voltage, wire model or outer diameter, wire loop, wire splitting number and splitting distance, ground wire model or outer diameter, phase arrangement (double-circuit or multi-circuit on the same tower is very important).

(2) Determination of the maximum allowable sag of fiber optical cable

In addition to the mechanical strength, the maximum allowable sag of the ADSS cable depends on the minimum distance between the lowest point of the cable sag and the ground (or crossover) and the location (or height) of the suspension point. The design of the location of the suspension point is directly related to the spatial potential of the point .

According to the relevant regulations or engineering requirements for the minimum distance between the lowest point of the fiber optic cable sag and the ground, the maximum allowable sag of the cable can be obtained. Engineering personnel should be clear: this is one of the important control conditions of the project.

(3) Tension-sag-span characteristics of ADSS optical cable

Calculation of tension-sag-span characteristics requires two conditions: design meteorological combination conditions and initial installation of cable sag.

5.The maximum application tension of ADSS fiber optic cable

The maximum application tension of ADSS should be determined according to the design load of the original power line tower. Under the condition that the line pole load permits, increasing the tension is beneficial to the realization of cross-span, but it may reduce the effective use of the cable span (control conditions change to The EDS of the cable is limited).

The engineering staff should determine the maximum working tension in each tensile section based on the spanning of each gear distance in different tensile sections. When ADSS must be hung in a certain position according to the requirements of line pole structure or spanning factors, such as 110kV line selected at the place where the space induced electric field is 20kV, ADSS fiber optical cable cannot choose PE sheath according to the convention. This situation should be determined according to the span and tension tower in each tension section of the line.

When necessary, the engineering staff selects ADSS fiber optical cables with different tensions and jacket types on a line based on the tensile section as a unit through economic comparison.

In short, in the actual engineering design, the engineering staff should combine the actual situation of the established power line. When the above conditions occur at the same time, the control conditions must be correctly selected to make the installation design of the ADSS fiber optical cable economic, safe, and reasonable.

ADSS shockproof and fitting

The strength design safety factor of the ADSS fiber optical cable should be determined under the condition that the design and meteorological conditions of the power line are consistent . According to the mature operation experience of power transmission lines in my country, the design safety factor of the ADSS fiber cable should not be less than 2.5. Like the metal stranded wire, the ADSS fiber optical cable is affected by wind and other environmental , and vibration will occur. Long-term vibration will cause fatigue damage to the fiber optical cable itself and the fittings. Therefore, the annual average operating tension of the ADSS fiber optical cable should be selected not to exceed 20% of the ultimate breaking force of the ADSS fiber optical cable, and corresponding anti-vibration measures should be taken.

1. Anti-vibration measures

At present, there are two anti-vibration measures: adding anti-vibration hammer and spiral anti-vibration whip (SVD). If additional anti-vibration hammer measures are adopted, a certain length of pre-twisted wire guard lines should be wound around the installation to disperse the stress. SVD is easy to construct and therefore widely used. Locale and laboratory tests show that the anti-vibration whip is very effective in reducing vibration levels.

The SVD should be installed according to the design requirements. Two or more SVDs can be connected in parallel or in series. Usually parallel connection is used. Generally, the maximum number can be 4 in parallel.

The industry generally believes that the installation position of the SVD is not sensitive to the anti-vibration effect. In order to prevent the anti-vibration whip from being too close to the end of the pre-twisted wire of the hardware to produce an arc, the greater the distance between the whip and the end of the pre-twisted wire of the hardware, the safer it is.

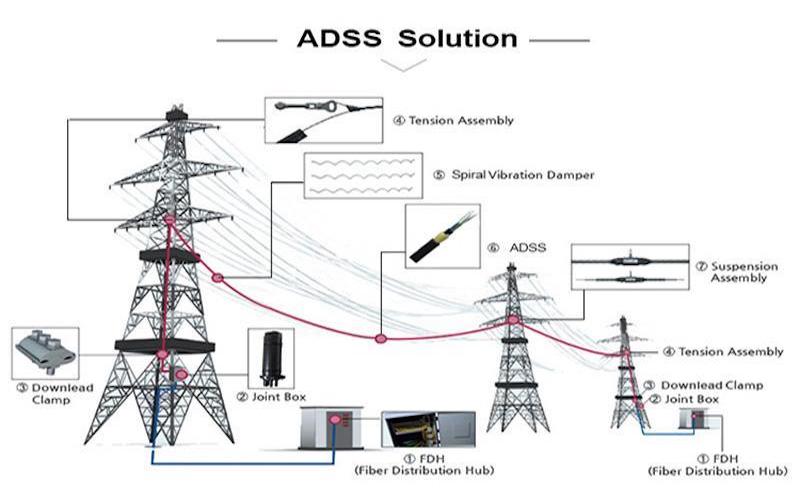

2. ADSS fiber optical cable fittings

ADSS fiber optical cable fittings mainly include tensile fittings, overhang fittings and splice boxes, usually supplied by ADSS fiber optical cable manufacturers. In recent years, ADSS metal fittings have been widely used and are in good operation.

UnitekFiber provides high-quality Indoor/outdoor optical fiber cables, MPO/MTP trunk cables and other fiber optical products according to customer needs. With more than 10 yeas developement, UniteFiber supplies high-density optical fiber products, Fiber optical patch panels, FTTH boxes, WDM wavelength division multiplexers, optical switches and other products, which are widely used in FTTx, telecommunications, 5G networks, data centers and other fields.

If you neen more information or support on fiber optical products offered by optical fiber suppliers, please don’t hesitate to contact us sales@unitekfiber.com, we will try our best to support you.